SWEETHY project

About SWEETHY

SWEETHY is a 4-year project, co-funded by the European Union, that aims at the development of an innovative electrolysis stack, capable of producing 20 g h-1 of hydrogen directly from seawater.

The project addresses the challenge of processing impure water by leveraging the innovative AEMWE (anion exchange membrane water electrolyser) technology and by developing new, more durable and cost-effective materials, capable of withstanding highly corrosive saline conditions. The developed electrolyser stack will ultimately secure > 2000 h of operation under a 1%/100 h degradation rate.

The overall sustainability and circularity of the electrolyser platform are ensured by the identification of symbiotic solutions in collaboration with external industrial partners for the efficient re-use of the electrolyser by-products (brine and other seawater salts, as well as heat).

Ultimately, the work of SWEETHY will enable the deployment of remote and distributed hydrogen production through the use of seawater and decentralized renewable energy sources.

This ambitious project brings together 9 organizations (2 research centres, 4 research and technology centres and 3 small-medium enterprises) across 7 European countries (Sweden, Italy, Spain, Germany, France, Norway and the Netherlands).

Objectives

Develop materials for catalyst, membrane, bipolar plates and porous transport layer capable to withstand sea water conditions

Development and testing of short scalable 0.5 kW stack

Find industrial partners capable of re-using bi-products from the electrolyser plant

Minimize environmental impact of electrolyzer

Concept

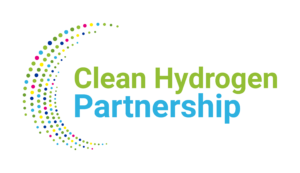

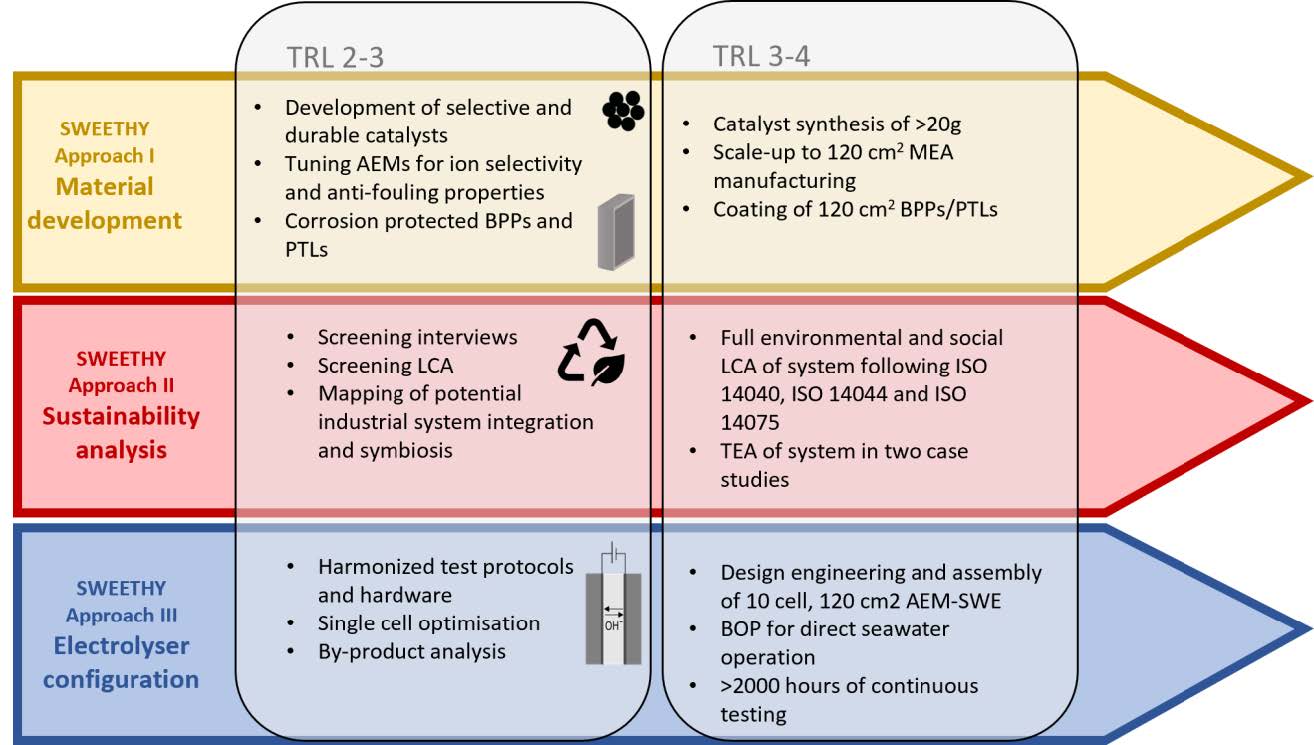

The project approaches the challenges of sea water electrolysis from three perspectives: The material development, The sustainability analysis and The electrolyser configuration. Materials for each electrolyzer component will be screened with the goal to improve their corrosion resistance in saline conditions. Sustainability and economical principles will integrate and guide the screening, in order to identify the most crucial trade-offs between cost, efficiency and durability. Finally, our materials will be integrated in a modular and scalable electrolyser configuration, fed by sea water and operating under dynamic conditions, typical of renewable energy sources.

Approach

The material development

- Innovation on the Electrocatalyst: Anode and cathode catalysts will be PGM-free and will be designed for durability, corrosion resistance and high selectivity in saline conditions and in alkaline pH. Two strategies will be followed for their preparation. One based on nanoparticles synthesis on a 3D support, one based on free-standing synthesis of foam, thanks to electrodeposition, or nanowires. Catalysts composition will be based on transition metals alloys, particularly of Ti and Ni.Innovation on Membrane: The baseline membrane material will be CENmat’s proprietary AionFLXTM. This will be modified to sustain salt water conditions, while ensuring mechanical resistance, OH– conductivity and preventing H2 permeation. It will be endowed with anti-fouling properties by application of an anti-fouling hydration layer and incorporation of zwitterionic materials. Finally, specific nanofillers will be introduced in the membrane structure to present the transport of harmful ionic species. Finally, biobased and recycled materials will be introduced in the membrane production.

- Innovation on Bipolar Plates and Porous transport layer: To prevent the corrosion of BPP and PTL during operation, Ti-based coatings will be applied on the surfaces of these components by either plasma spray or electrodeposition techniques.

The sustainability analysis

The socio-economic analysis aims at establishing the effects and risks of the electrolyser system by analyzing its interactions with the surrounding. This spans aspects such as value creation, biodiversity, freshwater accessibility/scarcity, climate and resources depletion impacts, employment opportunities, and health and well-being. The sustainability analysis will also directly participate in the technological development, by guiding material and technological choices guided by a circular and sustainable perspective. Attention will be given to the integration of the electrolyser in the local industry and energy system.

The electrolyser configuration

Based on previous work on electrolyser stack prototyping, partners will upscale and adapt to the AEMWE technology a modular stack concept, characterized by flexible pockets for cell insertion and hydraulic compression. This design is easily scalable and also allows for efficient extraction of the excess heat. The final design will comprise 10 cells and it will be able to deliver 20 bar pure H2 at the rate of 20 g h-1, during 2000 h operation. The stack will operate under dynamic conditions, emulating renewable energy supply, and recirculating Mediterranean sea water, with the addition of KOH to balance the pH. Finally, techniques such as filtering and centrifugation will be explored to extract valuable minerals (Mg) from the produced concentrated sea water.

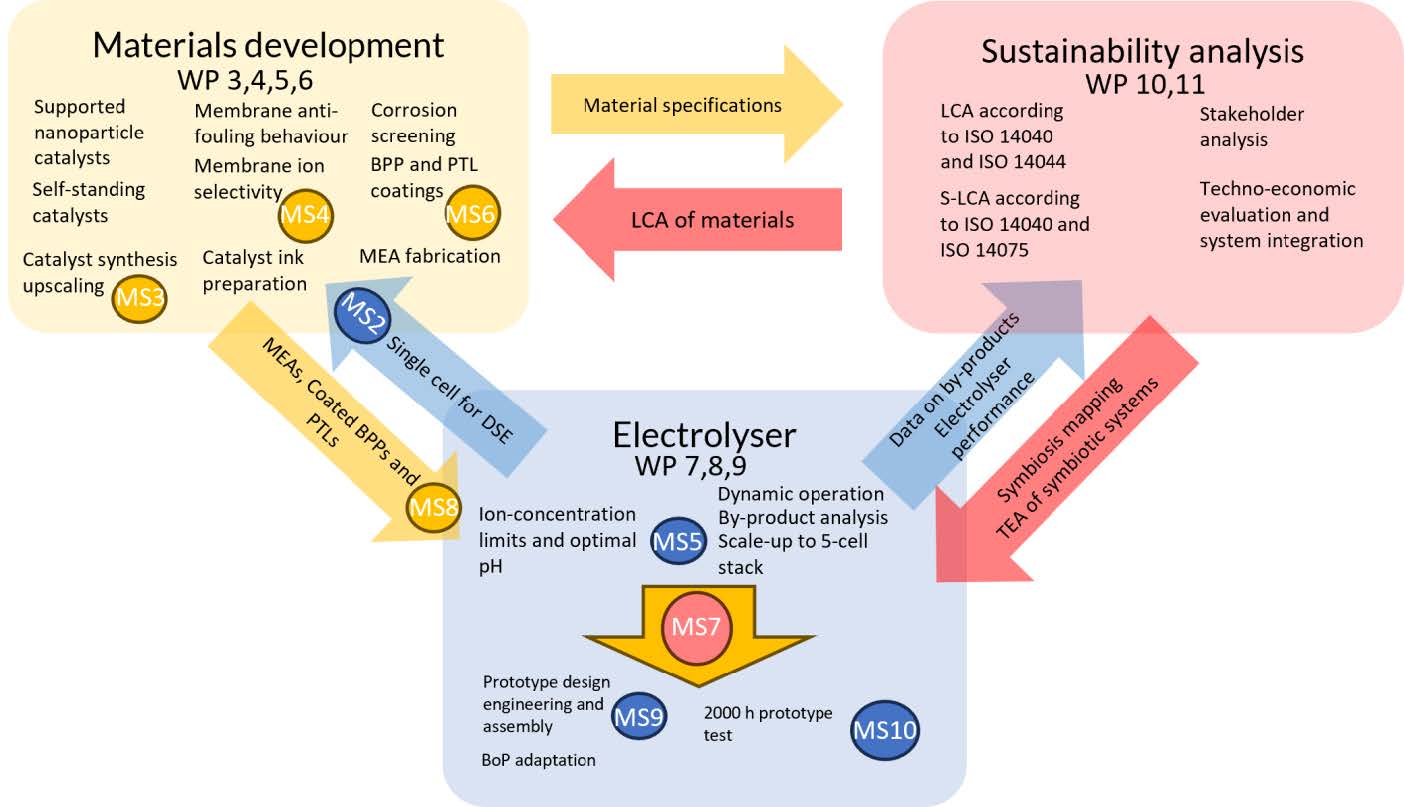

Structure

The work packages are organized around the central topics of the approach. WPs on material development (3-5) are the first ones to begin. Their results flow in WP6, where components are assembled in a MEA and tested at single cell level. WP10 on Sustainability analysis will support material and technological choices in this first phase. Testing protocols and short stack testing begin also in the first year of the project (WP7), focusing first on baseline materials and then on innovative components. WP7 will also investigate on a small scale the extraction of by-products from the stack. Finally, WPs 8 to 9, will focus on upscaling, engineering of the final stack design, design of the BoP and testing using direct sea water feed. From the second year, sustainability analysis in WP12 focuses on specific cases studies, evaluating the LCA, TEA and S-LCA of the electrolyzer system.